Manufacturing methods of violin basses.

|

Manufacturing methods of violin basses. |

|

|

To put it roughly, there are four different methods to build a wooden instrument body that looks (more or less) like a violin:

|

|

|

|

The solid body For the simplest method of the above you basically simply need a saw and a 3 inch timber. Unfortunately it only equals a violin if the viewer is far enough and not later than you lift it from the table, you know that this thing can't be hollow and has nothing in common with a violin - that's why I will not mention it further...

The hardest method is to build a real violin body with a thin rib, what needs lots of skills and lots of time.

|

||

|

As the name already says, a genuine violin body is made in the same way as a violin. First of all, the wood is being chosen and glued under pressure, as far as it has more then one layer.After that the back and the top plates are sawn and the complex rib construction is made. Tail and neckside ribs are connected with corner blocks to the c-bouts. A pretty fragile and time-killing work of art - and of cause a lightweight when it's finished! |

|

|

|

In the early years of the current millennium, Hofner officially introduced a variation of the genuine violin body by using a so called 'sustain block' on its cheaper violin bass models. This not really new construction connects both of the woodblocks on tail and neck shown above by a massive wood bar that absorbs most of the traction caused by steel strings. This allows the use of (ply)wood leading to less stable bodies but prevents the top from resonating as the old basses did. In so far the name 'sustain block' implies the advantage of better sustain (what might be true) but it takes away a bit of the characteristic warm sound that the old Hofners are famous for, even if the salesman says : 'Its not a bug, it's a feature'! For a comparison of different modern Hofner models look here. Right in between are the makers that take the best of the both methods above: The thick-rib body and the stacked-plywood body. When the cloning of american, german or italian instruments became profitable for the Japanese (and of cause later also for the Koreans and the Chinese), that depended on the same simple market law as it does in our days:

No surprise, most companies in the 60's went for the fast Yen, particularly facing the fact that they couldn't develop the needed skills overnight. Concerning the violin bass, this led to the question, how to build a hollow violin bass avoiding the complex rib construction of the german violin makers? So one fine day a wise guy developed the first method to sail round the difficulties of a real violin body by faking the thin rib simply with a couple of slats, approximatey the size of roof battens. They were placed at the rim between bottom and top of the body and milled in shape. |

||

| In

most cases two of these slats were enough to get the necessary height,

disregarding how many joints it might take. In order to hide that

workaround from the customers, the rib was veneered or on the cheaper

sticks heavily painted. Grinding down the paint of such a 60's veteran makes it obvious, you easily recognize the joints and the edges especially if the colour of the pieces differs. Here is by the way the reason for the tremendous differences in the heavyness of violin basses. While Hofner or Klira Basses hardly reach the 5 lbs mark, thick-rib vb's easily make twice the number! |

|

|

| Although

the thickness of this solid rib differed as the case arose, this method

required a different solution for the plug-in point. An usual

ts-socket

is way too short since its thread was dedicated for being mounted on

maximum

4-6mm materials. This is the reason, why the steelplate was used, until then only seen on solidbodies like the Les Paul guitar. So if you ever see the jack of a violin bass being mounted not directly in the wood of the rib but on a metal plate, be aware that this is very likely not a real violin body! |

|

|

When Sir Paul, after years of using the Rick on stage, reactivated his Hofner 500/1 in the early 90's, this suddenly caused a worldwide demand of violin basses again. Unfortunately at this time nearly all japanese productions had ceased to exist owing to a lack of demand in the 80's. The far east gold rush of the 70's was over and noone in sight to produce quantities of a competitive Hofner clone. As already in the late 60's it should be cheap and as close as possible to the Hofner, anything else wouldn't sell. Gibson of cause would have had experience enough in building a hollowbody bass and even the skills to make an own violin bass themselves - but they wouldn't be able to underprice Hofner respectively their famous piece of craftsmanship. If such an instrument could not be offered to a dramatically lower price as a Hofner, people would choose 'the original' , might have been their educated guess, perhaps still a bit under shock from their last-ditch attempt to sell their EB1 in the shadow of the high profile of the 500/1. As a good opportunity Gibson's budget-daughter Epiphone had already produced several series in far east and could step into the breach. As a difference to the methods 20 years ago, this time the production could be automated to a large extend. They developed a technique to build violin shaped bodies by stacking plywood boards that looked nearly like a genuine violin body when finished but were in fact a modern version of the thick-rib body. Epiphone introduced the Viola-Bass in the 90's, innumerable Far East companies should follow pretty soon with this method. |

||

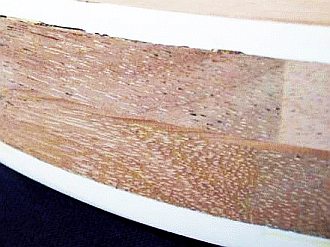

The stacked-plywood body The operation is very fast and easy: a punch, eating plywood plates on the one end, shitting violin bass shaped pieces on the other end, does the job. One is bottom, one is top, the rest is punched again to rings that are stacked with masses of glue, until the appropriate height is reached. Needless to say, that this plywood and glue chunk has nothing to do with the fragile construction of a violin or a violin bass. Because of the large amount of wood glue the vibration behaviour of the instrument ist completely different, even compared with the thick-rib veterans.That this different concept has major influence on the sound, especially if other components as tuners or pickups are from the bottom drawer, should make sense to everyone. right: view through the pickup hole on the plywood stack,the exterior rib is veneered and lacquered |

|

|

| It's

understood that we find on this modern piece that socket with its

steelplate as well, which you will hardly find on a

real violin bass (since it offers an easier method by simply drilling a

hole

into the thin rib). The stack of plywood rings cannot be arbitarily

thin

on its rib, otherwise it looses the stability. The result is the same

as

on the thick-rib basses: no normal jack is found with that enormous

length, so a metal plate is needed! As far as it's obvious I've branded instruments with this construction in the gallery as  . (Standard Chinese or Korean Plywood and Glue Chunk) in order to recognize them

immediately as non-vintage and non-genuine violin bodies! . (Standard Chinese or Korean Plywood and Glue Chunk) in order to recognize them

immediately as non-vintage and non-genuine violin bodies!right: removing the steelplate shows a side hole with a thickness several times the size of a genuine violin bass side. That's where the weight comes from! |

|

|